This is not just a resource embargo; it is also an industrial war that has lasted for over 70 years.

Everyone should have noticed the recent escalation in China-U.S. trade frictions. However, if you carefully review the news and speeches, you will find that this time, the focus seems to be somewhat different from that in April.

In the wave back in April, the core point was "trade deficit." This time, the term that has been repeatedly mentioned is: rare earths.

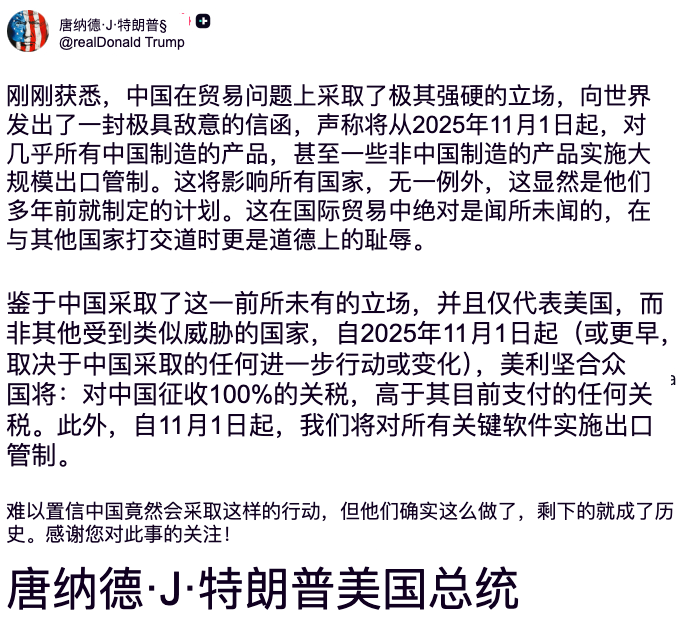

Even Trump tweeted twice: "Incredible" and "Unheard of."

You don't need to scrutinize all those tweets; you just need to feel one thing: the card of "rare earths" really makes Trump uncomfortable.

Why rare earths? Aren't they just a type of mineral? Why do some people say this is a "rare earth war"?

In fact, this is not just a resource embargo; it is also an industrial war that has lasted for over 70 years.

To understand this, let's start with the most basic question.

Why rare earths?

Are rare earths really that important?

Very important. Today's high-tech industries and military industries are completely dependent on rare earths.

For a concrete example, if China cuts off the supply of rare earths, the U.S. could see the F-35 fighter jet production halted in as little as 6 months. In as little as a year and a half, 7 out of 10 planes in a hangar could be grounded.

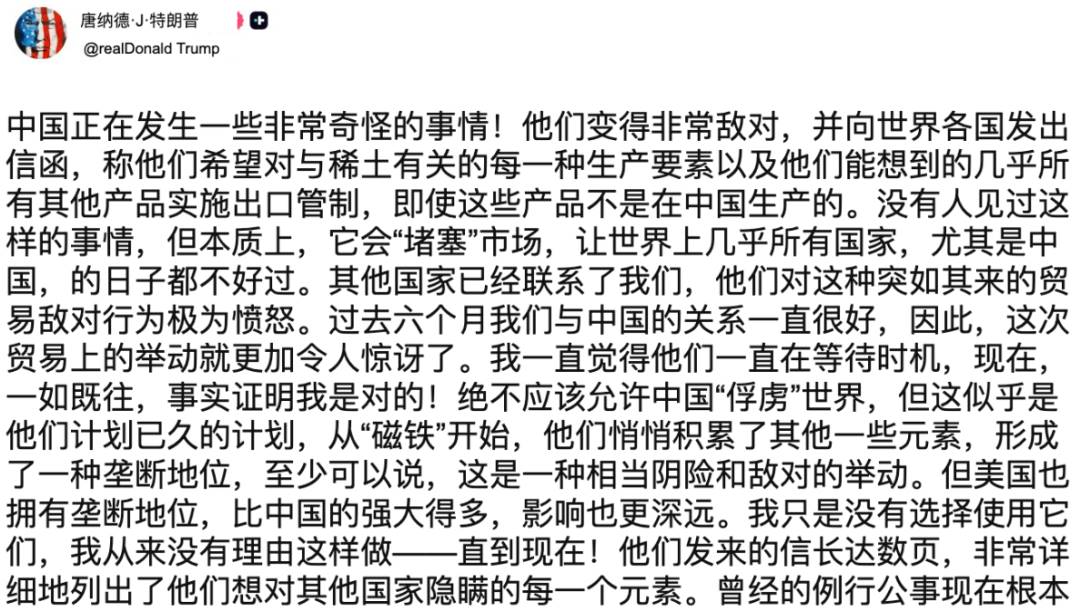

From a chemical perspective, rare earths are actually a collective term that includes 17 chemical elements, each with its unique function.

This might sound a bit abstract, so let me give a few examples.

For instance, neodymium, dysprosium, and terbium can generate a huge magnetic field in a very small volume. This is what enables mobile phone speakers, computer hard drives, and electric vehicle motors.

For example, europium, terbium, yttrium, and neodymium can precisely convert electrical energy into light, sound, and vibration. This is what allows for the various colors on mobile phone screens, speakers to play music, and the vibration feedback of mobile phone motors.

For instance, neodymium, samarium, terbium, europium, and dysprosium enable weapons to see far, hit accurately, and fly fast. This is what powers the F-35's engines, the precision guidance of missiles, and radar systems.

In simple terms, from mobile phone chips to missile aircraft carriers, the key behind it all is rare earths.

So, does this mean that the usage of rare earths is very high?

On the contrary, the usage of rare earths is actually very low. For example, an airborne AESA radar antenna weighing about 400 kg uses only a few hundred grams of rare earths, less than 0.1%. For a shipborne phased array antenna weighing about 5 tons, the core magnetic components use only a few dozen kilograms of rare earths.

In simple terms, rare earths are like salt. You don't use much, just a little. But if you lack that little bit, you can't start a fire or cook. For the U.S. chef, the salt they need must be bought from China.

Because, in the field of rare earth manufacturing, China currently has a dominant advantage.

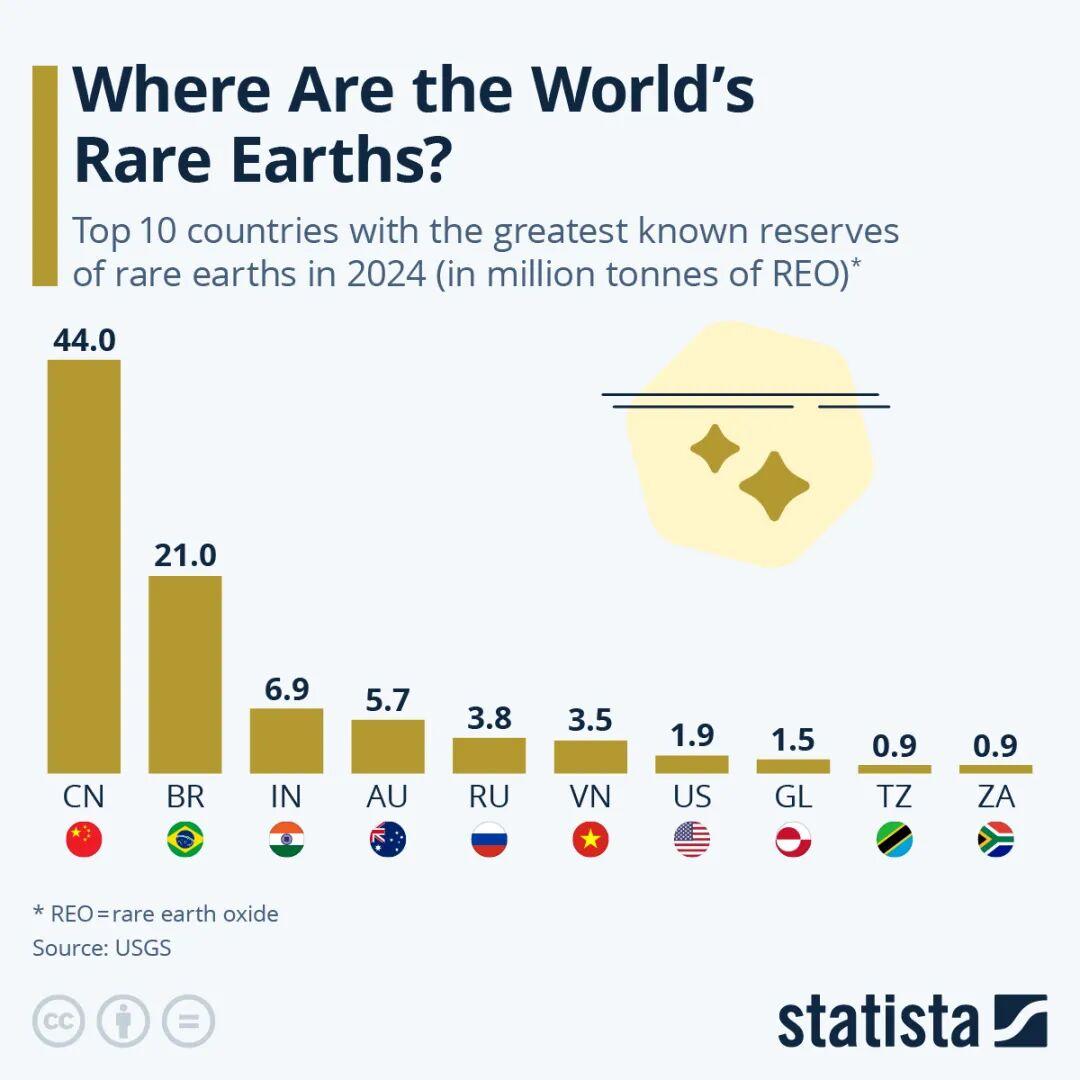

Looking at some data, China currently accounts for about 69% of the global rare earth smelting and separation capacity and over 90% of the processing capacity. In many key areas, "over 90% of the output is in China." Take the rare earth permanent magnet materials necessary for producing military weapons, for example. The global output is 310,200 tons, with China's output at 284,200 tons, accounting for 91.62%.

In other words, without China's supply system, the U.S. cannot find alternatives in the field of rare earth supply.

Now, what happens when the chef can't buy salt?

The planes won't fall immediately, but after a few months of using up rare earth reserves, changes will become apparent. A report from the U.S. Congress has estimated that if China completely cuts off rare earth supplies, the F-35 production line will have to stop in as little as 6 months. In as little as a year and a half, only 3 out of 10 planes may be operational. Moreover, important components like guidance systems and control chips will also be unavailable for replenishment. This means repairs will be impossible.

Unable to repair the old, unable to build the new. A cut-off in rare earth supplies directly stifles the renewal of U.S. military industry.

The same situation will occur in the U.S. high-tech industry. In comparison, the perception of those tech products will be stronger for the public. Mobile phones may become more expensive, electric vehicle performance may decline, and computer production capacity may rapidly decrease.

Just think, can this U.S. chef sleep soundly after seeing such a bill? Absolutely not.

Thus, the card of "rare earths" is indeed a "trump card." It has allowed China to choke the "neck" of the U.S.

How did it come to the point where the U.S. is being "choked" by China?

You might be curious; in the past, we often heard that the U.S. was always "choking" us on chips and systems. How did the tables turn this time, and now it's our turn to "choke" them?

This is precisely the most exciting part of the entire story.

Because China has spent over 70 years turning what the U.S. once looked down upon into our current advantage.

How did we achieve this? Let's look at it step by step.

First, you need to break a cognitive misconception. Although "rare earth" has "rare" in its name, it is actually not "rare" at all.

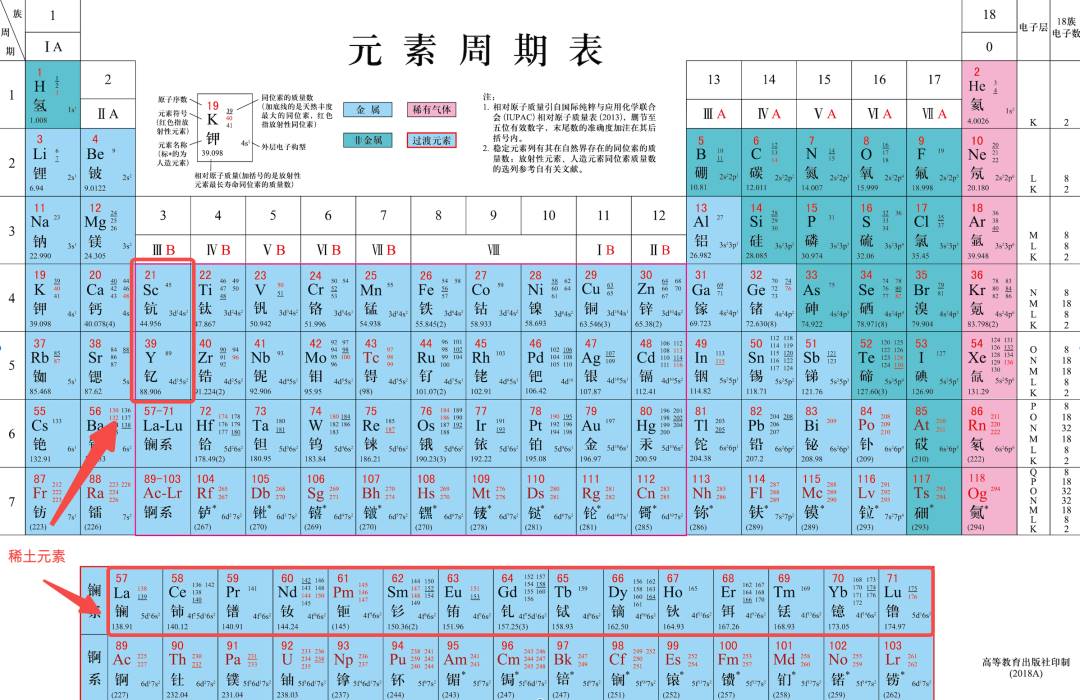

According to data from the U.S. Geological Survey in 2024, while China's rare earth reserves are the largest in the world, accounting for about 34% of the global total, countries like Brazil, India, Australia, Russia, Vietnam, and the U.S. also have certain rare earth mines.

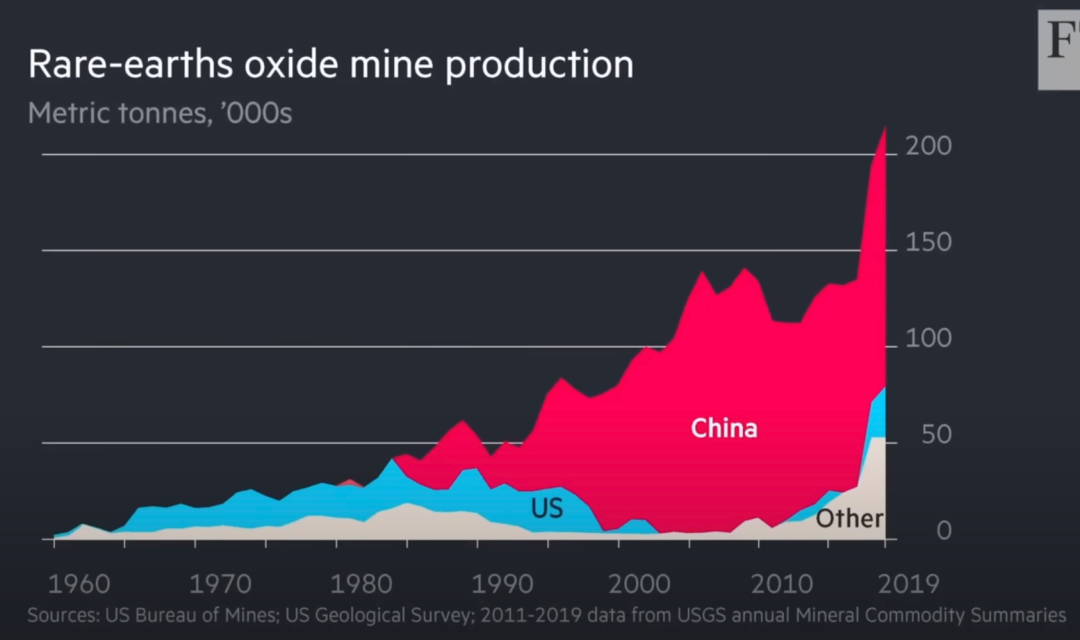

In fact, in the 1960s and 70s, the U.S. was the big brother in rare earth production. Not only did it have a large output, accounting for 70% to 90% of global rare earth production, but it also mastered the most advanced separation and purification technologies.

This indicates that the key to this "war" has never been about who has the bigger mine.

So, it's strange; why didn't this big brother continue to hold that position? Did he not want to be the big brother anymore?

Hey, you guessed it right; it was indeed "the U.S. itself that didn't want to be the big brother."

The turning point occurred in the 1980s. Americans discovered that mining rare earths seemed a bit "dirty." The process of producing rare earths would cause a lot of pollution, involving acids, heavy metals, and even toxic fertilizers. Moreover, it was very energy-intensive. Coupled with increasingly strict environmental laws in the U.S. at the time, the cost of rare earth production became increasingly high.

In the end, Americans did the math: domestic production had to comply with environmental laws, labor costs were high, and there were complaints from residents, making the costs too high. This "big brother" was feeling too constrained.

What to do? Outsource! To whom? To China. Research indicated that moving rare earth production from the U.S. to China could reduce unit costs by an estimated "30% to 70%."

At that time, China had a huge cost advantage. There were abundant rare earth resources, a large amount of cheap labor, and relatively lenient policies.

Thus, the wheels of history began to turn.

In the 1980s and 90s, a large number of small and medium-sized rare earth enterprises emerged like mushrooms after rain. Correspondingly, in 1985, a tax rebate policy for rare earth exports was introduced. From the late 1990s to the early 21st century, the rebate rate ranged from 13% to 17%.

At that time, it could be summarized as "disorderly mining and barbaric growth." If you mined one hill, I would mine two or even three. If you sold for 10 dollars, I would dare to sell for 5 or even 3 dollars. After various struggles, rare earths were even sold at rock-bottom prices. Of course, there was a cost; many places faced issues of over-exploitation and environmental pollution.

The ultimate result of this "barbaric growth" was that China became the world's largest rare earth producer in the late 1980s.

To Western countries at that time, this was simply a tremendous blessing. They no longer had to do the dirty, tiring, and expensive work; they could sit at home and enjoy extremely cheap rare earth products from China.

Thus, the U.S. did the math again. Since importing was more cost-effective than producing and selling domestically, why should they continue to produce and sell themselves? This led to the closure of the U.S.'s largest rare earth mine, Mountain Pass.

At the same time, the global rare earth industry underwent a restructuring, with many Japanese and European rare earth companies either exiting the market or scaling back their operations.

In this way, China, with its enormous production capacity and extremely low cost advantage, "outlasted" all its global competitors.

Up to this point, this is only the first half of the story.

You see, at this time, it is far from being able to talk about monopolizing the entire industry. It was only about large output, but the core technology and pricing power were still not in their hands.

Additionally, some might say, isn't this just using pollution to exchange for development? What's so great about that?

I want to say that today's Chinese rare earth industry has long since shed the "small workshop-style" high-pollution development. It has become a formalized, group-oriented, national-level industry.

The turning point appeared around 2010. The "national team" entered the scene.

The first step was "integration."

They integrated hundreds of small mines and factories across the country into "six major rare earth groups." This ended the price wars and achieved full-process control from mining, production to export. It also ended the barbaric development and reduced environmental pollution.

The second step was "regulation."

They established stricter regulatory policies. For example, starting in 2006, rare earth production quotas were implemented. In 2007, a rare earth export tax was introduced. In 2023, the export of certain rare earth processing technologies was banned.

The third step was "technological upgrading."

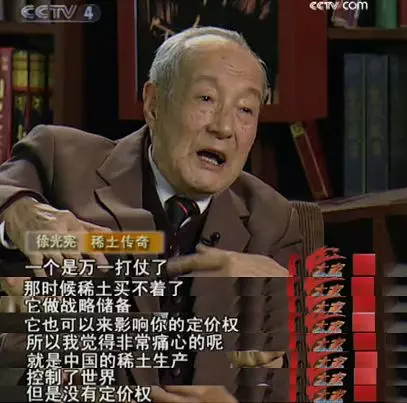

This was the most critical step. Here, we must mention a person known as the "Father of Chinese Rare Earths," Academician Xu Guangxian. His proposed "rare earth cascade extraction theory" can produce single rare earth elements with a purity of 99.99% at a lower cost.

When I saw various experiences of Academician Xu Guangxian, I was deeply moved. The history behind this is truly legendary.

In 1972, Xu Guangxian, who had just returned from a re-education school, received an urgent task: to separate the most difficult pair of "twin brothers" among rare earth elements—praseodymium and neodymium.

At 52, Xu Guangxian saw this not just as a chemical problem but as a matter of national economic sovereignty and national defense security. Seeing that China had the most rare earths in the world but lacked pricing power, Xu Guangxian felt very pained. He said:

"We felt very uncomfortable, so no matter how difficult it was, we had to tackle it."

Thus, a "war" belonging to Xu Guangxian began.

Separating praseodymium and neodymium was a very important step in rare earth separation technology. At that time, the mainstream international method was "ion exchange." This method was like using tweezers to pick out salt from sand, which was feasible but slow and expensive. Moreover, it was not suitable for large-scale industrial production.

When Xu Guangxian started, he encountered a dead end. What to do?

Surprisingly, he chose the "solvent extraction method," which at the time seemed very risky.

The principle of this method is like laying dozens or hundreds of small filters, allowing the rare earths to be "extracted" layer by layer, becoming purer as it goes. However, at that time, no company in the world had succeeded.

So why did Xu Guangxian dare to try?

Because he had previously engaged in extraction research for nuclear fuel for the country. Extraction is extraction, whether it's nuclear or rare earth.

Thus, Xu Guangxian and his team began their expedition. During the day, they immersed themselves in the laboratory, using the most primitive method—"shaking funnels"—to simulate industrial extraction. Imagine, a process with dozens or hundreds of layers; if one layer goes wrong, all previous efforts are wasted. At that time, each person worked over 80 hours a week. At night, Xu Guangxian would dive into the data from the day, performing various calculations and deductions.

Finally, he discovered the "constant mixed extraction ratio law," establishing the "cascade extraction theory."

Even more impressive followed. Based on this, Xu Guangxian and his team extracted a mathematical model with over 100 formulas. How powerful is this model? Factory technicians can simply input ore data into the model, and it will automatically calculate the best production parameters. In other words, it simplified the originally complex rare earth production process.

You see, he not only invented new technology but also created a new system.

If the technological breakthrough proved Xu Guangxian's expertise, his subsequent actions showcased his admirable spirit.

In 1978, he founded the "National Cascade Extraction Workshop." He taught the entire theory, formulas, and design methods to technicians across the country without reservation and for free. Soon, this technology, which was considered a top secret abroad, became a "common process" mastered by China's township enterprises. This laid the foundation for the later flourishing of the rare earth industry in China.

In the early 1990s, China exported a large amount of single high-purity rare earths, completely rewriting the global rare earth industry landscape.

It can be said that it was he who transformed our rare earths from being sold "by the ton" to being sold "by the gram."

Even today, the foundation of China's rare earth industry still stems from Xu Guangxian's "war."

All these changes brought about the most direct result: the price of rare earths was "driven down."

For example, there is something in fighter jets called "phased array radar," which uses a material called "neodymium-iron-boron permanent magnet." Neodymium-iron-boron permanent magnets use rare earths. In the 1990s, the cost of this phased array radar typically reached several million dollars.

But now? Phased array radar is used in weather stations, as automotive radar, and placed in 5G base stations. Instead of several million dollars, you can buy it for just a few thousand dollars.

From complex military technology to "ubiquitous" civilian technology, the underlying reason is the sufficient maturity of the rare earth industry.

You see, China has spent over 70 years transforming from a "trainee" that could only serve dishes and wash dishes into a chef holding "unique skills." About 90% of global refining, about 93% of permanent magnet manufacturing, and 99% of heavy rare earth element processing must be completed in China.

Here's the interesting part. Over the past few decades, the significant increase in China's global rare earth market share has not been taken seriously by Western countries.

I can't help but wonder, with things being this way, did no one notice? I saw some analyses online suggesting that the main reason is that China's rare earth raw materials are too cheap and the supply is abundant. Western countries, which are concerned about environmental issues, would not consider developing their own rare earth industries.

In simple terms, since there is enough to eat and fill up, there is no concern about not having enough.

This good situation lasted until 2010.

Japan was cut off from rare earth supplies for nearly two months. Rare earth prices skyrocketed, even increasing by more than ten times.

At this point, it seemed that everyone suddenly realized that something was not quite right.

Not long after, the U.S. restarted its only domestic rare earth mine, Mountain Pass, while also seeking alternative suppliers in Japan and Australia.

However, the U.S. lacks the technology for rare earth refining. So even if they mine rare earths themselves, they still have to be sent to China for refining.

The underground reserves are not monopolized; the real power lies in the production capacity and technology in hand.

This is also why, in just 70 years, the tables have turned.

Seeing this, you might have another question: Since everyone knows rare earths are important and has now reacted, why don't they hurry to catch up?

Since rare earths are so important, why don't other countries develop them?

In fact, everyone can develop them. But the problem is that it takes at least 10 years to get started.

Rare earth technology is not considered cutting-edge technology; the U.S. was also capable of it in the past. The difficulty lies in the need for a complete set of elements to establish their own rare earth industry: money, talent, technology, and environmental protection.

Let's look at them one by one.

First, the capital barrier.

How much does it cost to build just a rare earth separation plant?

For example, Australia's Lynas is the world's second-largest rare earth producer after China. It has invested over $1 billion to build a separation plant in Malaysia. This is just one factory. To build a complete supply chain from the mine to the smelting plant to the processing plant would require tens of billions or even hundreds of billions of dollars, taking at least 5 to 10 years.

For capital, this investment is too risky and the returns too slow. Who would be willing to wait?

Second, the technology barrier.

The difficulty is not in theoretical knowledge but in the hard-to-replicate "craftsmanship."

How to understand this? For example, there is a "solvent extraction method" in rare earth separation. This step is actually very tedious. You have to pass the rare earth solution through hundreds or even a thousand extraction tanks. In each tank, you must precisely control the pH value of the solution, with no deviation of even a fraction.

Imagine if you made a mistake in the 131st tank but didn't realize it. You wouldn't find out until you completed the subsequent 800 steps. Wouldn't that be frustrating?

To ensure success, the only way is to continuously experiment and accumulate data.

In simple terms, it's like a chef saying, "a pinch of salt, a spoonful of vinegar, and simmer on low heat." But how much is "a pinch"? What size is that "spoon"? What exactly is "low heat" in terms of degrees and minutes? If you ask the chef, he will only say that these are all long-term "muscle memory" and "unique feel." You see, it's all true; he's not lying to you.

Countries like Vietnam and Brazil, which also have rich rare earth mines, either lack technology and a complete industrial system or have to import equipment from China. Their situation reflects the dilemma faced by many countries: even if they get the "recipe," they can't understand it and lack the "kitchenware."

As of 2023, among the 469,758 rare earth patents searched in Incopat, China holds 222,754, accounting for about 47.4% of the total, maintaining a leading position globally. Experts estimate that China's separation technology is at least 5 to 10 years ahead of foreign countries.

Third, the talent barrier.

What is even harder to replicate than technology is people. Western countries have experienced a talent gap in the rare earth field for nearly two generations.

If you want to cultivate talent from scratch, how long would it take?

An expert in the rare earth field, from undergraduate to doctoral studies and then to practical experience in a company, would take at least 10 to 15 years. To support a complete industrial chain, a team composed of hundreds of such talents is needed.

There is also a more practical problem: there are no teachers and no students. The experts who understood the field best back then have likely retired, leading to a gap in knowledge and experience. As for students, given that the rare earth industry in Europe and the U.S. has disappeared for thirty years, how many students would be willing to study this "niche" specialty?

Fourth, the policy barrier.

Even if the issues of talent, technology, and funding are resolved, the public's most pressing concern about environmental protection cannot be avoided.

In the past, local residents would complain about noise and pollution. Today, the public's reaction may be even stronger.

This challenge is likely the hardest for Western countries to overcome.

So, let's return to the question: Why don't other countries develop rare earths themselves?

It's not that they don't want to; it's that they can't. Even if they start learning, it will take at least 10 to 20 years to cover the 70 years that China has traversed.

Looking at the U.S., even though it has restarted its only domestic rare earth mine, Mountain Pass, it still lacks skilled workers, policy support, and refining capacity. Mountain Pass is expected to produce 1,000 tons of neodymium-iron-boron magnets by the end of 2025. This is still less than 1% of China's 138,000-ton capacity in 2018.

Experts predict that at the current pace, it may take until 2040 for the U.S. to achieve self-sufficiency in rare earth supplies.

But that is still 15 years away. Meanwhile, this "rare earth war" has already begun.

Final Words

Phew, it's done. By now, you should understand what rare earths are all about and why they can be used to "choke" the U.S.

The phrase "the tables have turned" sounds easy to say, but behind it lies the heavy burden of several generations over seventy years.

The reason we can play the "rare earth trump card" today is that we must not forget the price paid by countless predecessors to forge this card for us, the later generations.

When the U.S. abandoned this dirty and laborious industry out of commercial logic, it was scientists like Xu Guangxian who bent down, picked up this "heritage," which seems incredibly precious today.

In that impoverished era, they devoted their lives to simple laboratories, pouring their hearts into those seemingly dull bottles and jars. It was this perseverance, confidence, and determination that made it possible for "dirt" to turn into "gold."

It also bears the immense sacrifices of countless industrial workers. They dug with their hands in clouds of dust, stood firm beside pungent solutions, and through sweat and sacrifice, gradually built this industry's absolute advantage.

Thus, there is no casual success in this story, nor is there any unearned strength. The reason we have the confidence and capital to "arm wrestle" with the U.S. today is precisely because of this group of people who endured the greatest hardships and bore the heaviest burdens for us in the past, turning a bad hand into a winning one.

They are the true trump card behind the "rare earth" card. And they are the ones we should be most grateful to today.

Because the history we witness today is precisely the echo of history.

免责声明:本文章仅代表作者个人观点,不代表本平台的立场和观点。本文章仅供信息分享,不构成对任何人的任何投资建议。用户与作者之间的任何争议,与本平台无关。如网页中刊载的文章或图片涉及侵权,请提供相关的权利证明和身份证明发送邮件到support@aicoin.com,本平台相关工作人员将会进行核查。